What is multi-slide die casting?

Multi-Slide Die Casting is a process where four independent perpendicular slides are used to produce very complex and accurate castings; in some cases, even six slides can be used at angles other than 90 degrees. This was used particularly for small zinc components, but now even magnesium casting and other metals are possible. The die casting industry is innovative and advancing with technologies. And the industry has produced multi-slide die casting machines to cast many different metals, especially in small parts.

About multi-slide tools

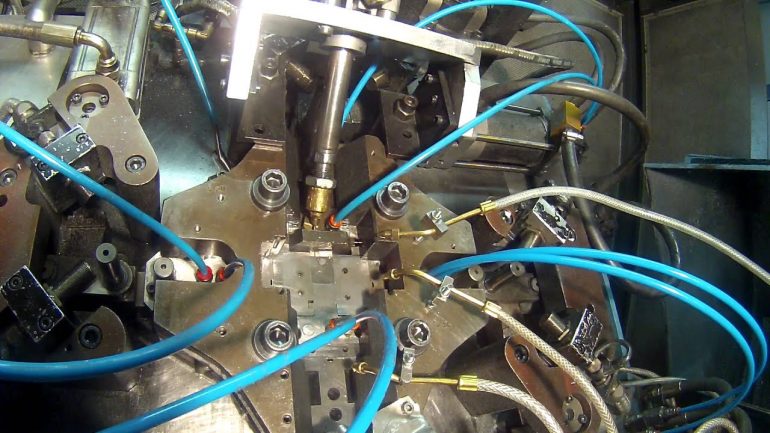

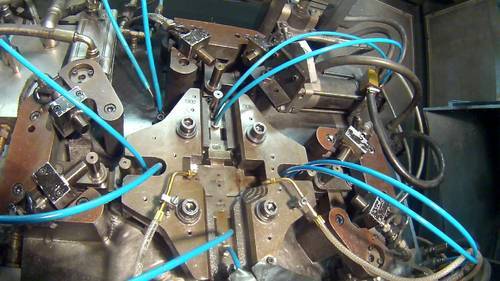

The creation and operation of the equipment and how the process takes place make multi slide die casting machine different from traditional hot-chamber die casting. Using a two-part tool in traditional hot-chamber die casting makes creating parts with complex geometries difficult and expensive. And Multi-slide tooling uses four perpendicular slides to make complex and precise castings of molten metals. So, with multi-slide die casting technologies, the customers can design and cast the metal in any complex geometry. The die block, sliders, crosshead, and cover plate comprise the multi-slide tool. Each slide carries a die block, where there is a cavity or cores on its face, which complete the whole cavity and runner profile into which the molten metal is poured. This increased the speed of the process and reduced the discarded piece.

How does it work?

The multi-slide die blocks are on sliders and fit perfectly into a crosshead, making the process easy and convenient for the opening and closing of sliders. These components are held together by a cover plate fastened to the tool’s top.

During the closing and opening processes, each slide moves independently. This independent movement of slides makes the process smooth and flexible, which assures part integrity and reduces tool damage. After that, in no time, the metal solidifies and is released from the mold by air bust and gathered in a cushioned device.

Benefits of multi-slide die casting machines

● Low cost in tools, energy, and labor

● Precise casting and with most complex dimensions

● High-Quality and reduction in discarded material

● The need for the second operation reduces

● Production increased as multi-slide die casting machines operated at up to 75 cycles per minute.

The multi-slide die casting machines improved the casting of metals and gave precise parts to the customer at a low cost. It’s effective, especially for the production of small parts with excellent dimensions.